- Machine Tools

- Machining Centers

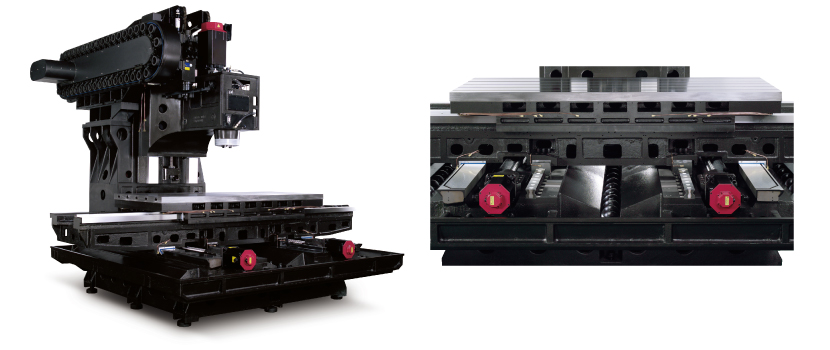

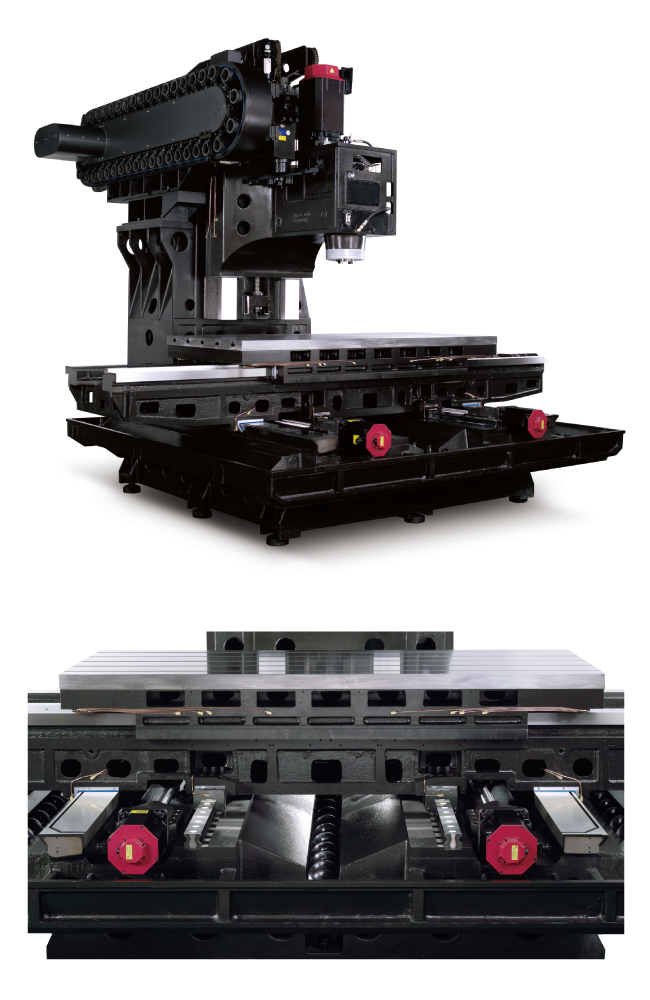

- FV1890S / FV2090S

Outline

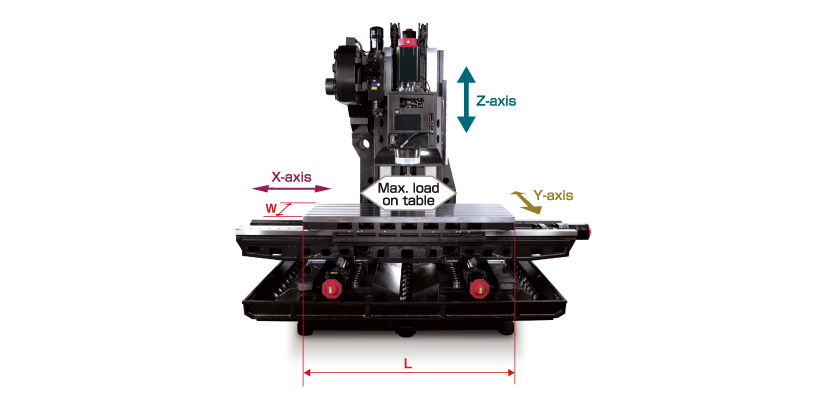

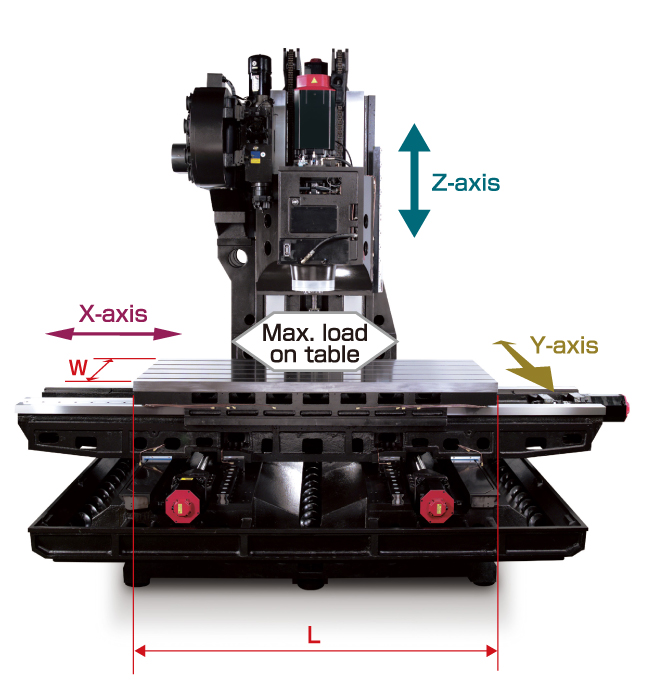

Y-axis hybrid slide & dual ball-screw

A dual ball-screw is used on the Y-axis feed mechanism, the area which is subjected to the highest load, and stable positioning is made possible by using a highly-rigid square slide together with a linear guide with high guiding accuracy.

4-slide Y-axis with little overhang

By supporting the table and X-axis slide base with four Y-axis slides, workpiece overhang is reduced and accuracy is stabilized.

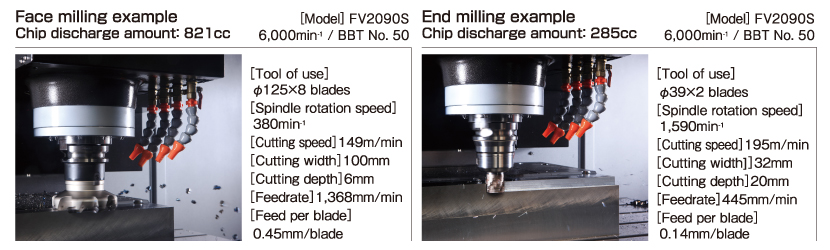

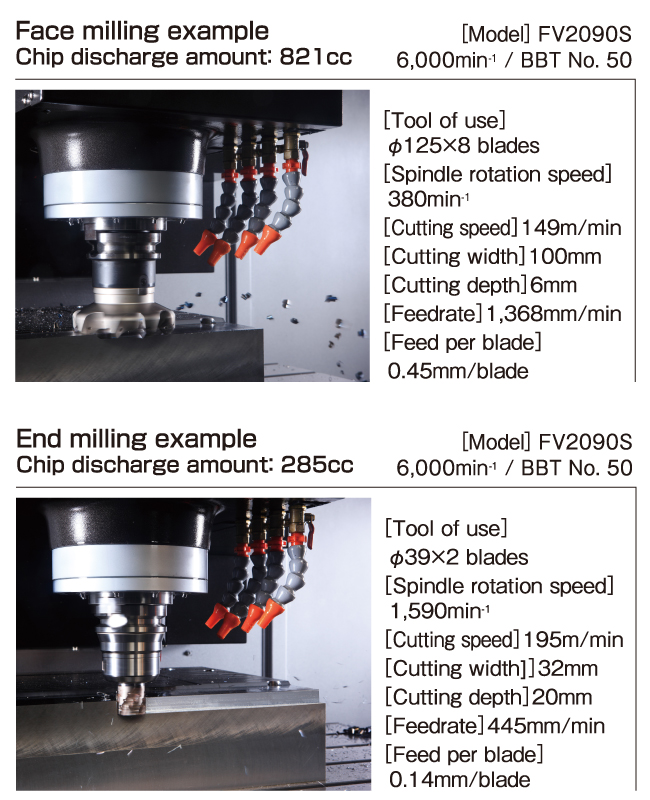

Machining example

Specification

|

|||||||||||||

| Table |

|

||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Stroke |

|

||||||||||||

| feed rate |

|

||||||||||||

| Spindle |

|

||||||||||||

| ATC |

|

||||||||||||

| Dimensions & Weight |

|

[ ] shows optional specifications.

※ For standard specifications only.