- Machine Tools

- Grinders

- GF50MS / GF50MH

Outline

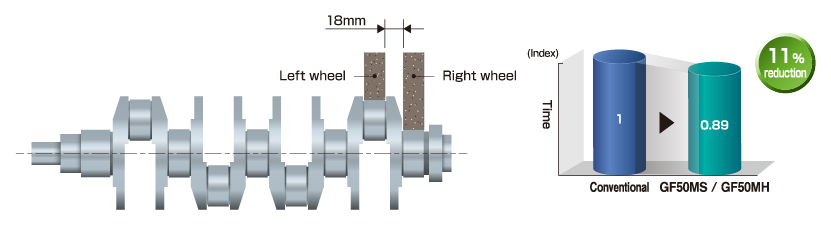

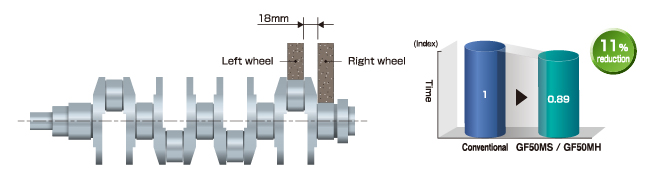

Reduced no. of grinding steps due to closer proximity between the left and right wheels

By making the closest proximity between the left and right wheels 18 mm, compared to the previous 50 mm, it has become possible to grind the pin and adjacent journal simultaneously. This has reduced the number of grinding steps and cycle time. (Not needed with shoulder grinding specifications)

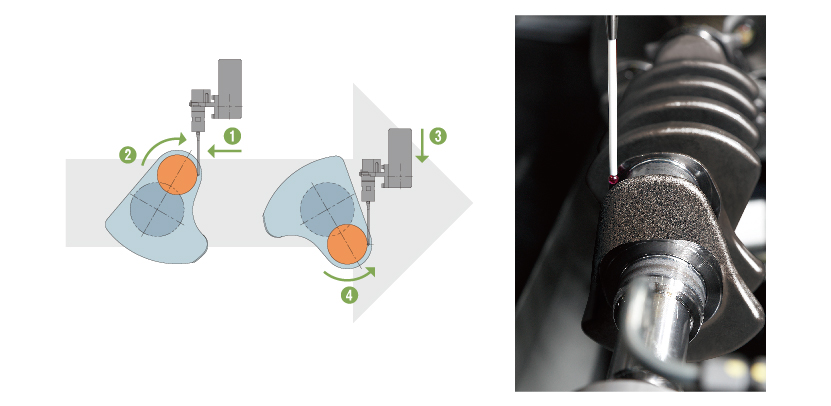

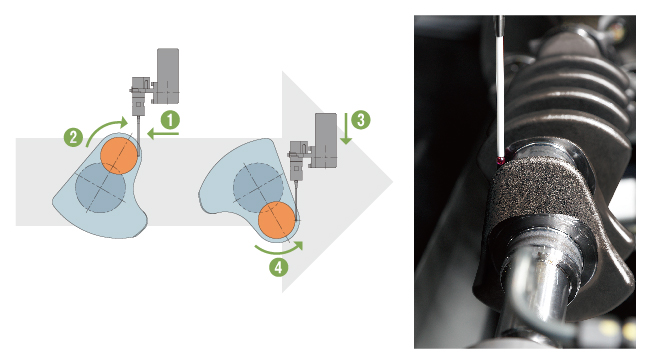

Reduced set-up changeover due to a pin phase indexing system

Increase productivity with a pin phase indexing system using a touch sensor. It supports various workpieces with differing pin diameters and pin strokes, significantly reducing set-up changeover time. (also used for wheel diameter control and endface indexing)

Specification

|

|||||||||||||

| Swing over table |

|

||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Distance between centers |

|

||||||||||||

| Grinding diameter |

|

||||||||||||

| Max. workpiece diameter |

|

||||||||||||

| Wheel |

|

||||||||||||

| Wheel head traversing method |

|

||||||||||||

| Machine floor space (width × depth) |

|

||||||||||||

[ ] shows optional specifications.