- Machine Tools

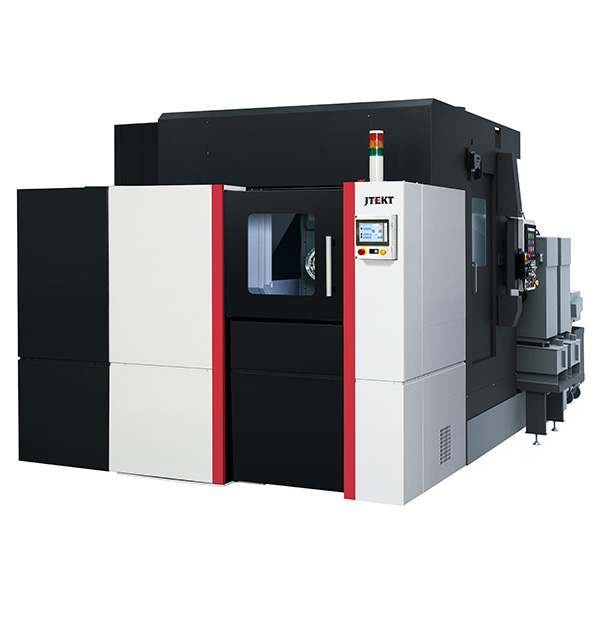

- Gear skiving centers

- GS200H / GS700H

Outline

Contributing to the reformation of gear component machining

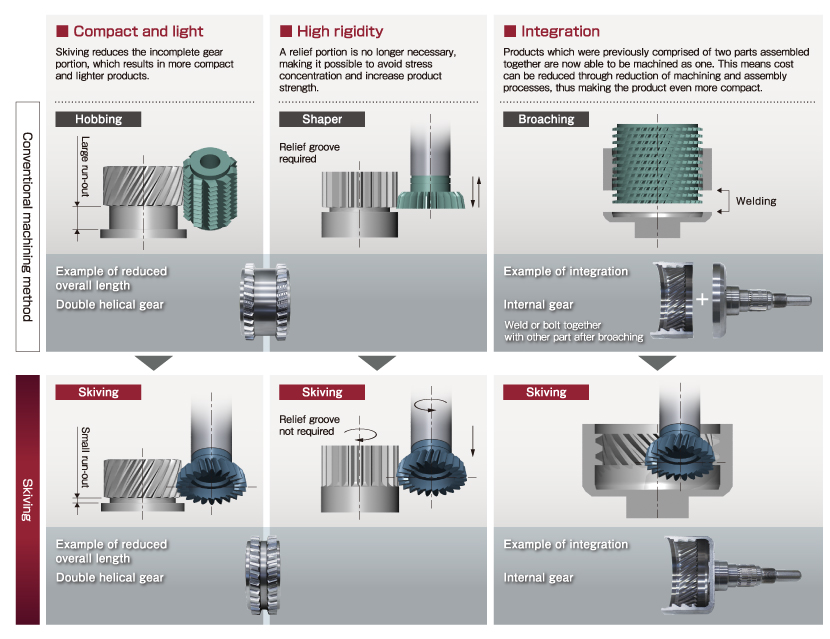

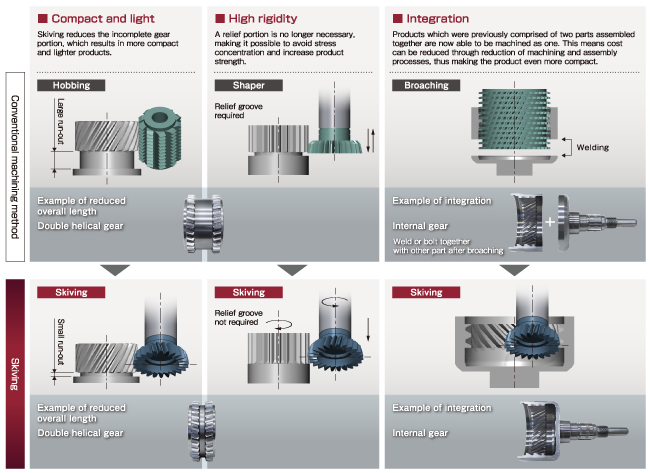

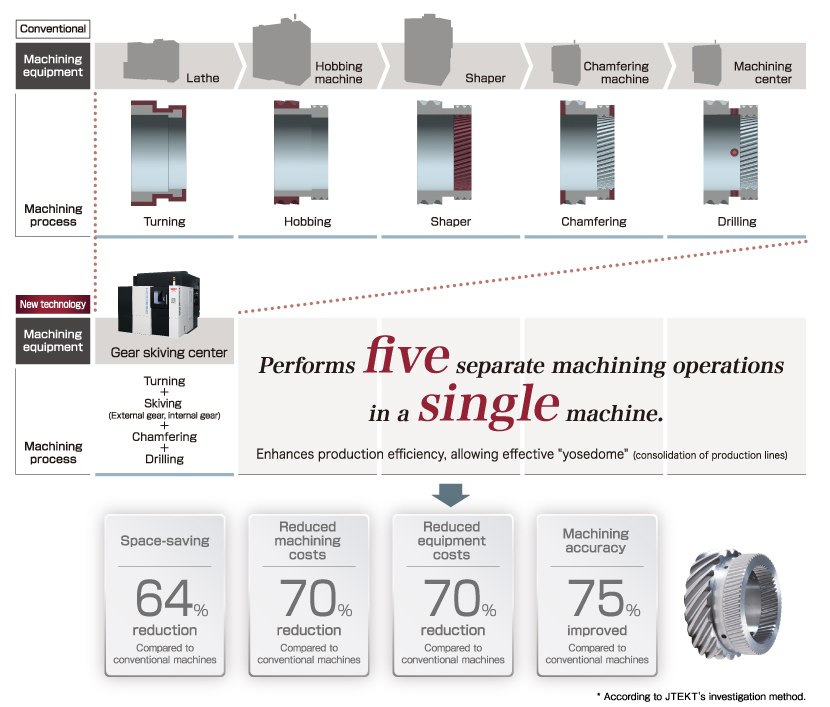

JTEKT's gear skiving centers make it possible for machining of gears that were previously difficult to process, thus contributing to customer's product reformation.

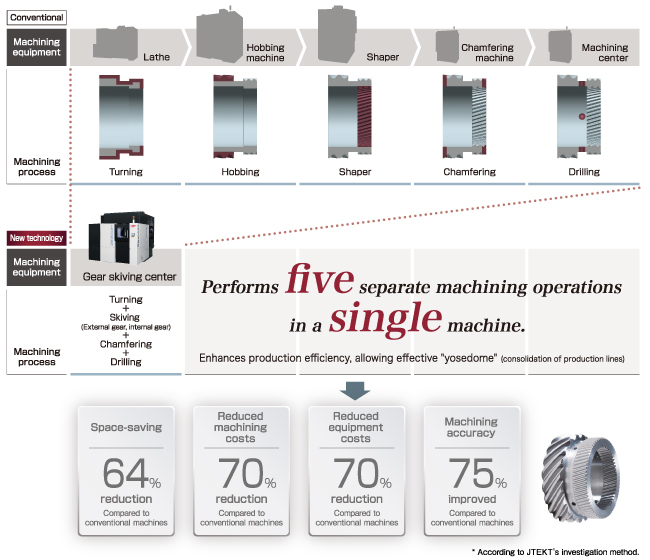

All gear machining processes rolled into one

JTEKT's gear skiving centers reduce set-up changeover time through not only integrating gear cutting, but also all processes from turning to drilling on one machine. This machine increases productivity at the same time as improving machining accuracy by completing all processes in a single chuck grasp.

Specification

|

|||||||||

| Feed unit |

|

||||||||

|---|---|---|---|---|---|---|---|---|---|

| Spindle |

|

||||||||

| Workpiece spindle |

|

||||||||

| ATC |

|

||||||||

| Control |

|

||||||||

| Floor space (Width×depth) |

|

[ ] shows optional specifications.

※1 If the option of 8 distributor ports is used, the workpiece RPM will be 1,500 min-1.

Machining gear specifications

|

|||||||||

| Workpiece size |

|

||||||||

|---|---|---|---|---|---|---|---|---|---|

| Max. module |

|

||||||||

Please contact our sales staff for more information.